EVA foam, short for Ethylene-Vinyl Acetate foam, has become a ubiquitous material across various industries due to its exceptional versatility, durability, and cost-effectiveness. From sports equipment and footwear to packaging and cosplay props, EVA foam has found its place as a reliable choice for numerous applications. This article delves into the characteristics, types, production process, benefits, and applications of EVA foam, highlighting its widespread use and potential.

How do you make the EVA foam?

EVA foam is manufactured through a process called copolymerization, which involves the combination of ethylene and vinyl acetate monomers. The process typically follows these steps:

- Monomer Preparation: Ethylene and vinyl acetate monomers are prepared separately. Ethylene is derived from crude oil or natural gas, while vinyl acetate is produced through the reaction of acetic acid and ethylene.

- Copolymerization: The ethylene and vinyl acetate monomers are mixed together in specific proportions, typically ranging from 2% to 50% vinyl acetate, depending on the desired properties of the foam. The mixture is then heated and subjected to high pressures in the presence of a catalyst, which initiates the copolymerization reaction.

- Polymerization Reaction: Under high heat and pressure, the monomers undergo a chemical reaction known as copolymerization. The vinyl acetate monomer units integrate with the ethylene monomer units, forming long chains of ethylene-vinyl acetate copolymer.

- Foam Expansion: Once the copolymerization reaction is complete, the resulting ethylene-vinyl acetate copolymer is melted and mixed with a blowing agent, usually a chemical compound that releases gas upon heating. This mixture is then poured into molds or onto a moving conveyor belt.

- Foaming Process: The copolymer mixture containing the blowing agent is subjected to controlled heat, causing the blowing agent to release gas and create bubbles within the polymer matrix. As the gas expands, it forms a cellular structure throughout the material, resulting in a foam.

- Cooling and Solidification: After the foaming process, the foam is cooled to allow it to solidify and stabilize. This step ensures that the foam retains its cellular structure and physical properties.

- Finishing: The solidified foam is cut into sheets or desired shapes. It may undergo additional processes, such as laminating, die-cutting, or surface treatments, depending on its intended application.

The specific manufacturing techniques and equipment used may vary depending on the desired characteristics of the EVA foam, such as density, thickness, and cell structure. The process parameters, including temperature, pressure, and blowing agent selection, can also be adjusted to achieve the desired foam properties.

What’s the EVA foam types?

EVA foam is available in different types or variations, each designed to meet specific needs and applications. The main types of EVA foam include:

- Standard EVA Foam: Standard EVA foam is the most common type and is widely used across various industries. It offers a balance of softness, flexibility, and durability. Standard EVA foam is available in different densities, thicknesses, and colors, making it suitable for a wide range of applications.

- Cross-linked EVA Foam: Cross-linked EVA foam, also known as XLPE foam (Cross-Linked Polyethylene foam), undergoes a cross-linking process during manufacturing. This process enhances the foam’s properties, including improved dimensional stability, resistance to compression set, and better heat resistance. Cross-linked EVA foam is often used in applications that require higher performance and greater resistance to chemicals, heat, and stress.

- Microcellular EVA Foam: Microcellular EVA foam, also known as EVA microcell foam or fine-cell EVA foam, has a fine cellular structure with small, tightly packed cells. This type of foam offers a smoother surface, higher density, and improved strength compared to standard EVA foam. It is commonly used in applications that require enhanced impact absorption, vibration dampening, and superior surface finish.

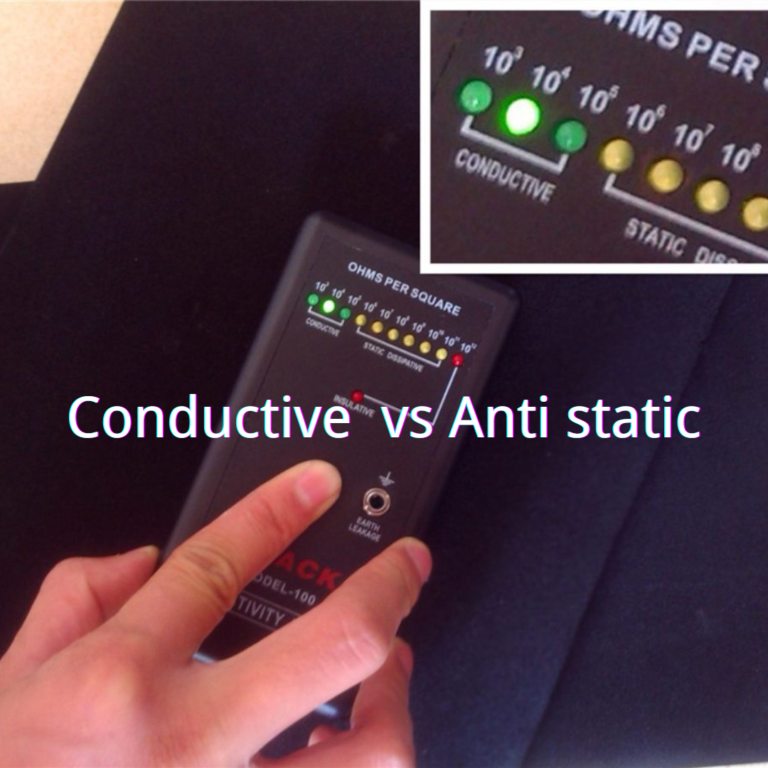

- Anti-Static EVA Foam: Anti-static EVA foam is specially formulated to provide static dissipative properties, making it suitable for applications in sensitive electronic industries. It helps to prevent the buildup and discharge of static electricity, reducing the risk of damage to electronic components. Anti-static EVA foam is often used in packaging, shipping, and storage of electronic devices.

- Flame-Retardant EVA Foam: Flame-retardant EVA foam is formulated with additives that enhance its fire resistance properties. It is designed to self-extinguish and inhibit the spread of flames when exposed to fire. This type of foam is commonly used in applications that require compliance with fire safety regulations, such as automotive interiors, aircraft components, and construction materials.

- UV-Resistant EVA Foam: UV-resistant EVA foam is formulated with additives that provide enhanced resistance to ultraviolet (UV) radiation. This type of foam is less prone to degradation, discoloration, and cracking when exposed to sunlight or outdoor environments. UV-resistant EVA foam is often used in outdoor applications, such as marine decking, outdoor furniture, and sports equipment.

It’s important to note that the availability of specific types of EVA foam may vary depending on manufacturers and suppliers. Different combinations of properties, densities, and thicknesses can also be customized to meet specific application requirements.

EVA Foam Colors

EVA foam is available in a wide range of colors, offering versatility and customization options for various applications. The color availability may vary depending on manufacturers, suppliers, and specific product lines. Here are some common colors of EVA foam:

- Black: Black is a popular color for EVA foam and is widely available. Black foam is commonly used in applications such as footwear, sports equipment, cosplay props, and industrial applications.

- White: White EVA foam is also commonly found and is often used in applications where a clean and neutral appearance is desired. It can be easily painted or dyed to achieve different colors.

- Gray: Gray EVA foam provides a neutral and professional appearance. It is commonly used in industrial settings, packaging, and automotive applications.

- Red, Blue, Green, Yellow, and Other Primary Colors: EVA foam is available in a range of vibrant primary colors, making it suitable for various artistic, craft, and educational purposes. These colors are often used in children’s play mats, arts and crafts projects, and classroom materials.

- Pastel Colors: EVA foam in pastel shades, such as light pink, baby blue, mint green, and lavender, is popular for applications that require a softer and more delicate aesthetic. These colors are commonly used in children’s products, baby items, and creative projects.

- Neon and Bright Colors: Neon or bright-colored EVA foam is utilized for eye-catching and attention-grabbing applications. These vibrant colors are often used in advertising displays, signage, costumes, and sports equipment.

- Custom Colors: Depending on the manufacturer or supplier, it is often possible to request custom colors for EVA foam. This allows for greater customization to match specific branding requirements or design preferences.

It’s worth noting that color availability may vary based on the specific type and thickness of the EVA foam. Some manufacturers may offer a broader range of colors, while others may have more limited options. When sourcing EVA foam, it is advisable to inquire about the available color choices from the manufacturer or supplier.

What’s the EVA foam Characteristics and Composition?

Characteristics and Composition:

EVA foam is a closed-cell foam material made by combining ethylene and vinyl acetate using a copolymerization process. The resulting foam has a distinctive combination of properties that make it suitable for a wide range of applications. Key characteristics of EVA foam include:

- Lightweight: EVA foam is lightweight, making it easy to handle and work with, particularly for applications where weight is a crucial factor.

- Softness and Flexibility: The foam has a cushion-like softness and flexibility that provides comfort, impact absorption, and shock resistance. This makes it ideal for applications that require padding or protection.

- Water and Moisture Resistance: EVA foam exhibits excellent resistance to water and moisture, preventing degradation and maintaining its performance over time.

- Thermal Insulation: EVA foam possesses good thermal insulation properties, making it useful in applications that require temperature regulation or protection against extreme heat or cold.

EVA foam benefits and Advantages:

The unique properties of EVA foam offer several advantages, contributing to its widespread popularity:

- Cost-Effective: EVA foam is a cost-effective material compared to other foam options, such as polyurethane foam. Its affordability makes it accessible to a wide range of industries and applications.

- Ease of Processing: EVA foam is easy to cut, shape, mold, and bond, making it a versatile material for various manufacturing and DIY projects. It can be worked on using basic tools and equipment.

- Customizability: EVA foam is available in different densities, thicknesses, and colors. It can be easily customized through die-cutting, heat shaping, or laminating to meet specific design requirements.

Applications of EVA Foam:

The versatility of EVA foam has led to its utilization across a diverse range of industries and applications. Here are some notable examples:

- Footwear and Orthotics: EVA foam is extensively used in shoe soles, insoles, and footbeds due to its cushioning properties, shock absorption, and comfort. It provides excellent support and helps reduce fatigue.

- Sports and Fitness Equipment: EVA foam is found in various sports and fitness equipment, including yoga mats, exercise mats, boxing gloves, helmets, and protective padding. It offers impact resistance, grip, and comfort.

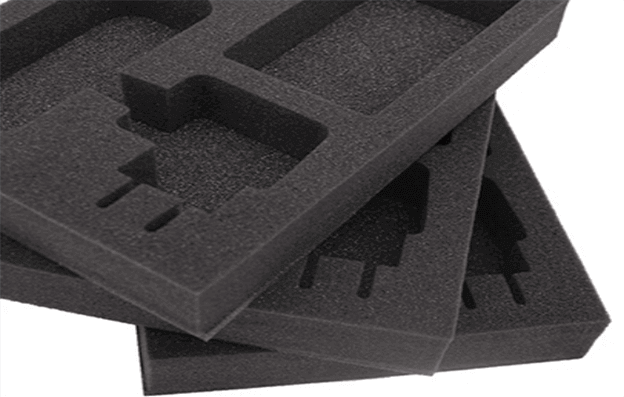

- Packaging and Transportation: EVA foam is used as protective packaging material to safeguard delicate items during shipping. It is also utilized in automotive interiors, such as door panels and instrument panels, for its noise and vibration dampening properties.

- Arts, Crafts, and Cosplay: EVA foam has gained popularity among artists, crafters, and cosplayers. It is used to create props, costumes, armor, masks, and intricate designs due to its ease of shaping, lightweight nature, and affordability.

- Medical and Orthopedic Devices: EVA foam is employed in the production of medical splints, orthopedic supports, prosthetic padding, and cushioning for various medical applications. Its softness, flexibility, and hypoallergenic properties make it suitable for these purposes.

Conclusion

EVA foam has established itself as a versatile and reliable material across a broad spectrum of industries. Its lightweight nature, softness, flexibility, and affordability have made it an