What’s Anti Static Foam

Anti-static foam, also known as ESD foam, due to the addition of a special polymer chain in the raw materials so that the finished product is willing to permanently dissipate static electricity. The finished product has good mechanical strength and heat resistance, good impact strength and strong chemical corrosion resistance.

Its anti static performance will not be changed because of environment, time and temperature. Therefore, it is widely used in LCD production assembly line, mobile phones, 3G terminals, computers / especially notebook computers, optoelectronic components, PCB board workshop turnover and electronic products which are easy to produce static electricity in transportation.

Anti-static foam can effectively release the static charge accumulated on the surface of the object, so that it will not produce charge accumulation and high potential difference; it can greatly reduce the damage rate of electronic products in the production process, reduce the cost, and improve the product quality and profit.

With anti-bending, anti-aging, high bearing strength, tension, compression, tearing, high temperature, made of packing box-type turnover box can be used for both turnover and finished product shipping packaging, lightweight, durable, stackable.

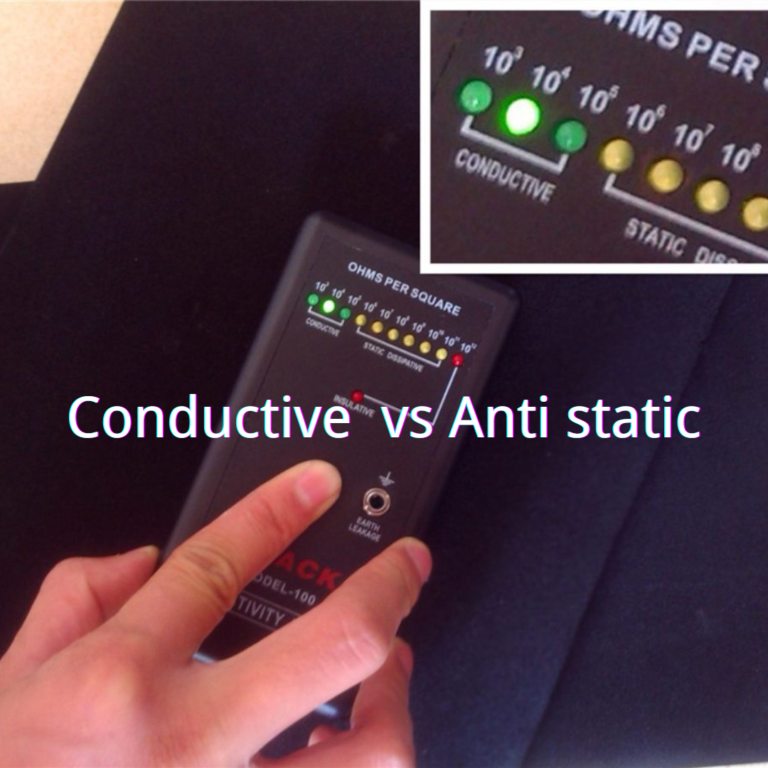

What is the Difference of ESD Foam and Conductive Foam

ESD foam also called anti static foam. The difference between esd foam and conductive foam mainly on the resistance. The resistance of anti-static foam is 10e6-10e11 Ω, and the resistance of conductive foam is 10e3-10e6 Ω.

Take ESD PE foam and conductive PE foam for example.

Antistatic foam is a new type of polymer functional material with permanent antistatic effect, which is made by chemical, physical modification, high energy electron beam radiation cross-linking foaming and other processing technology.

Conductive foam is a kind of foam formed by extrusion of polyethylene or modified polyethylene with conductive fillers and anti static agents, cross-linked by radiation and foamed at high temperature.

The electrostatic half-life of conductive foam is much smaller than that of anti-static foam, and the electrostatic voltage of conductive foam is much lower than that of anti-static. However, both of them can release charge automatically, and conductive foam is more suitable for electronic products with high electrostatic sensitivity.

How Does the Anti Static Foam Working ?

Generally anti-static foam is designed and manufactured according to the dimensions provided by customers to achieve the most reasonable loading, and multiple foam overlap, effective use of factory space, increase the storage capacity of electronic components, PCB board, dust-free workshop components, and save production costs.

It is widely used in ESD protection in four types: ESD PE foam, EVA foam, EPE foam and PU foam. It is used for anti static control with surface resistance from 10e6 to 10e9.

There are four ways for static control:

- To maintain a certain humidity environment

- Laying anti-static floor or carpet

- Semi conductor devices should be placed in anti-static foam tray or anti-static plastic bags.

- Operators should be in the wrist with anti-static hand strap