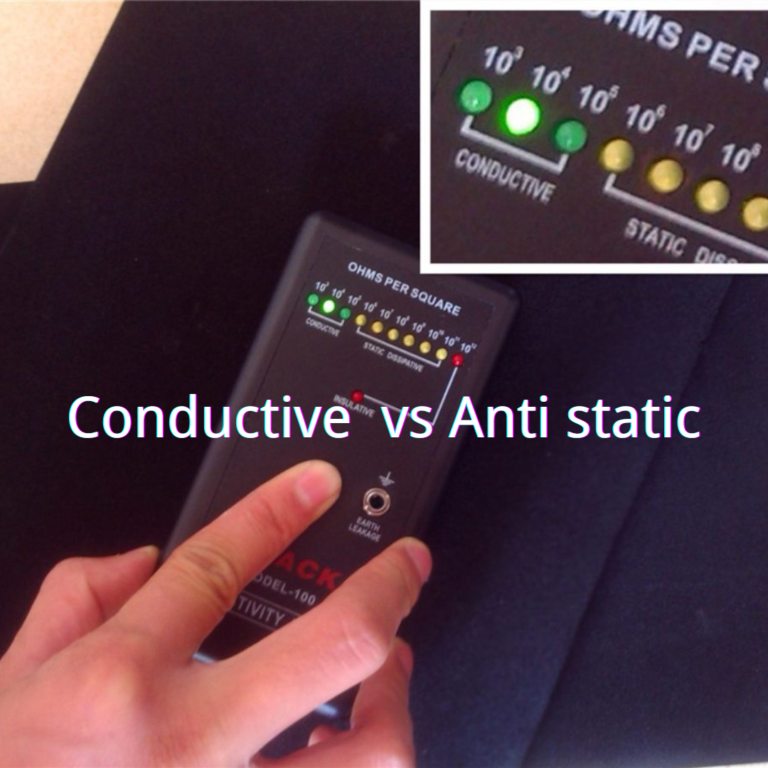

ESD, or electrostatic discharge, is a common occurrence in the electronics industry, where electrostatic charges can cause significant damage to sensitive electronic components. ESD foam is a type of foam that is designed to provide protection against these charges, while conductive foam is designed to provide a pathway for these charges to dissipate.

ESD foam, also known as anti-static foam, differs from conductive foam primarily in terms of resistance. The resistance of anti-static foam ranges from 10e6-10e11 Ω, while conductive foam has a resistance of 10e3-10e5 Ω.

Let’s take ESD PE foam and conductive PE foam as examples.

Anti-static foam is a kind of polymer functional material that provides permanent anti-static protection. It is made using chemical and physical modifications, high energy electron beam radiation cross-link foaming, and other processing technologies. Anti-static foam is a new type of polymer functional material with a permanent anti-static effect. It is made by chemical, physical modification, high energy electron beam radiation cross-link foaming, and other processing technology.

Conductive foam is a type of foam made by extruding polyethylene or modified polyethylene with conductive fillers and anti-static agents, cross-linked by radiation, and then foamed at high temperature. Conductive foam is designed to provide a pathway for electrostatic charges to dissipate quickly and safely, minimizing the risk of damage to electronic components.

While both anti-static foam and conductive foam can discharge charge automatically, the electrostatic half-life of conductive foam is much shorter than that of anti-static foam. In addition, the electrostatic voltage of conductive foam is much lower than that of anti-static foam. As a result, conductive foam is more suitable for electronic products with high electrostatic sensitivity.

Properties of Anti-Static Polyethylene Foam

- Excellent electrical conductivity, foam surface resistance: 10e6-10e9

- Density: 2.5-6.25 lb/ft

- Low charging anti-static properties – minimizes electrostatic charge generation

- No chemical corrosion: It does not corrode components and packaging

- Good buffer performance, ideal for device protection

- Provides protection from physical shock during handling, packaging, shipping, and storage of ESD-sensitive devices

- Ideal for long-term use

- Easy to customize through die-cutting, lamination, etc.

- Non-contaminating, non-corrosive, and non-sloughing

- Temperature resistance: maximum 80℃.

Usage Considerations for Anti-Static Polyethylene Foam

- Not recommended for lead insertion applications

- The foam does not discolor over time when exposed to the environment

- The foam surface resistance will change slightly when cutting or laminating

Properties of Conductive Foam

- Conductive foam surface resistance: 10e3-10e5

- Density: 5-6.25lb/ft

- Permanently conductive; will not lose electrical properties – can be used in applications where permanent ESD properties are required

- Improved packaging against shock and vibration

- Provides protection from physical shock during handling, packaging, shipping, and storage of ESD-sensitive devices

- Durable, resilient, attractive, and lightweight

- Chemical resistance: resistant to organic solvents, acids, bases, etc.;

- Non-contaminating, non-corrosive, and non-sloughing

Usage Considerations for Conductive Foam

- Better value for long-term applications

- Not recommended for applications where static dissipative properties are required

In conclusion, anti-static foam and conductive foam materials have similar properties, with their main difference being conductivity. While one is conductive, the other is anti-static. The choice between the two foam types ultimately depends on the customer’s needs and cost considerations.

If you have any questions, please don’t hesitate to ask.