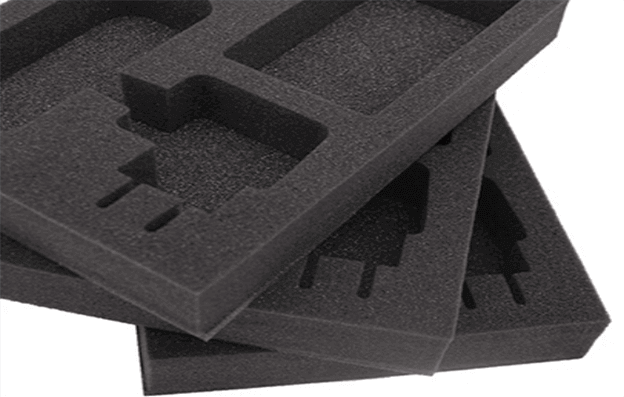

ESD foam in black color with 10mm thickness refers to ESD foam materials that are specifically manufactured with a black color pigment, 10mm is very popular sizes. The black color is often preferred in ESD foam products due to its aesthetic appeal and the ability to hide dirt or smudges more effectively. Here are some key points about ESD foam in black.

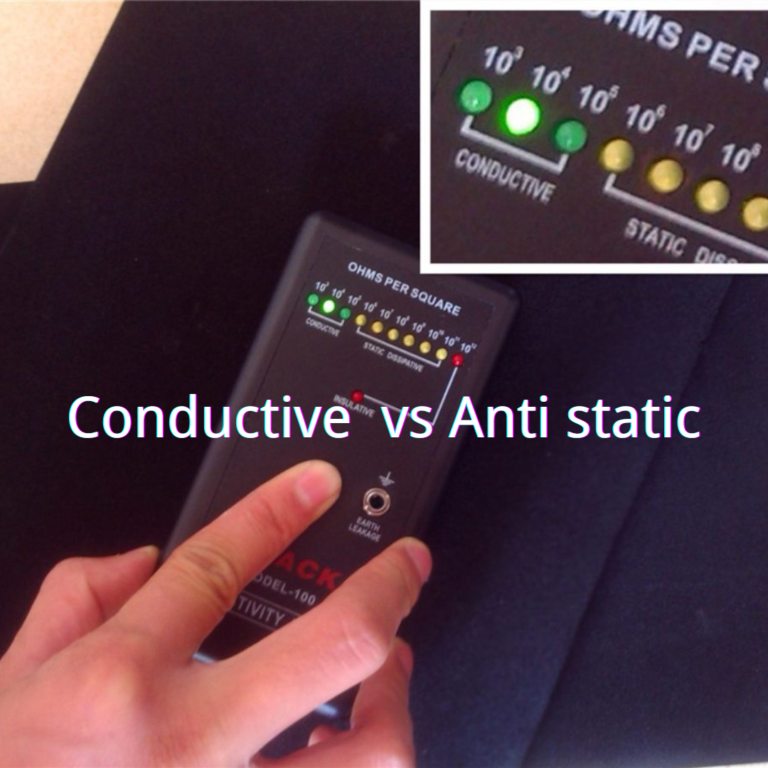

- ESD Protection: Black ESD foam possesses the same essential properties as other ESD foam materials, providing protection against electrostatic discharge. It has controlled surface resistivity that allows it to dissipate static charges and prevent the buildup of static electricity, minimizing the risk of damage to sensitive electronic components.

- Cushioning and Protection: Like other ESD foam variants, black ESD foam offers excellent cushioning and impact absorption properties. It can protect delicate electronic components from physical damage during storage, transportation, and handling.

- Enhanced Visual Contrast: The black color of ESD foam can provide enhanced visual contrast, making it easier to identify and locate electronic components or tools placed on or against the foam. This contrast can be particularly helpful in industrial or manufacturing settings where multiple components or items need to be organized.

- Cleanroom Compatibility: Black ESD foam can be manufactured to meet the cleanliness requirements of cleanroom environments. It can be produced with low particulate or low outgassing properties, ensuring it meets the necessary cleanliness standards.

- Versatile Applications: Black ESD foam plates can be used in various applications where ESD protection is essential. Some common applications include electronic component packaging, workstation mats and liners, tool organization, transportation and storage of sensitive devices, and more.

It is important to note that while black ESD foam is widely available, the exact specifications and properties may vary depending on the manufacturer or supplier. When sourcing black ESD foam, it is advisable to communicate your specific requirements to ensure that the foam meets the necessary ESD standards and any other desired characteristics for your intended application.