Searching for high-quality anti-static foam products in your area? Look no further! In this comprehensive guide, we will explore everything you need to know about finding top-notch anti-static foam products near you. Whether you are in need of foam for packaging delicate electronic components, protecting valuable items during shipping, or preventing the buildup of static charges in manufacturing processes, we have got you covered.

Choosing the right anti-static foam products is crucial to ensure the safety and integrity of your goods. From conductive to dissipative foam, this guide will walk you through the different types of foam, their features, and applications. We will also provide tips on how to select the right foam products based on your specific requirements.

Don’t settle for less when it comes to protecting your sensitive electronic equipment or valuable merchandise. Our guide will help you find trusted suppliers who offer top-quality anti-static foam products that meet your needs. With our assistance, you can locate the best products near you and ensure the utmost protection for your goods. So, let’s get started on your journey to find quality anti-static foam products today!

What is anti-static foam?

Anti-static foam is a specialized foam material that is designed to dissipate static electricity. It is made from a variety of materials, including polyurethane, polyethylene, and polystyrene, and is available in a range of different densities and thicknesses. Anti-static foam can be used for a variety of applications, including packaging, shipping, and manufacturing.

Importance of using anti-static foam products

Using anti-static foam products is critical for protecting sensitive electronic components and other valuable goods. Static electricity can cause damage to electronic components, leading to malfunction or failure. Anti-static foam helps to dissipate static charges and prevent them from building up, providing an extra layer of protection against damage.

In addition to protecting electronic components, anti-static foam is also useful for protecting other electronics during shipping and transportation. It can help to prevent damage from shock and vibration, ensuring that your items arrive at their destination in pristine condition.

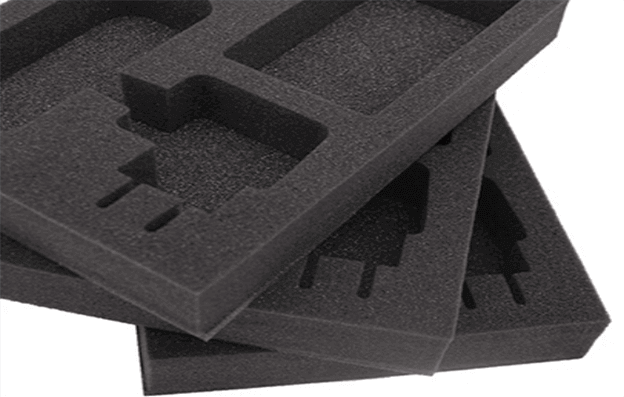

Common applications of anti-static foam products

Anti-static foam products are used in a wide variety of applications. Some of the most common applications include:

1.Electronic packaging

Anti-static foam is commonly used to package electronic components, such as circuit boards, computer parts, and other sensitive electronics. The foam helps to protect these components from static electricity and other forms of damage during shipping and transportation.

2. Manufacturing

Anti-static foam is also used in manufacturing processes to prevent the buildup of static electricity. It can be used as a lining for workbenches or floors, or as a covering for tools and equipment.

3. Shipping and transportation

Anti-static foam is often used to protect goods during shipping and transportation. It can be used to line shipping crates, wrap items for added protection, or as a cushioning material to prevent damage from shock and vibration.

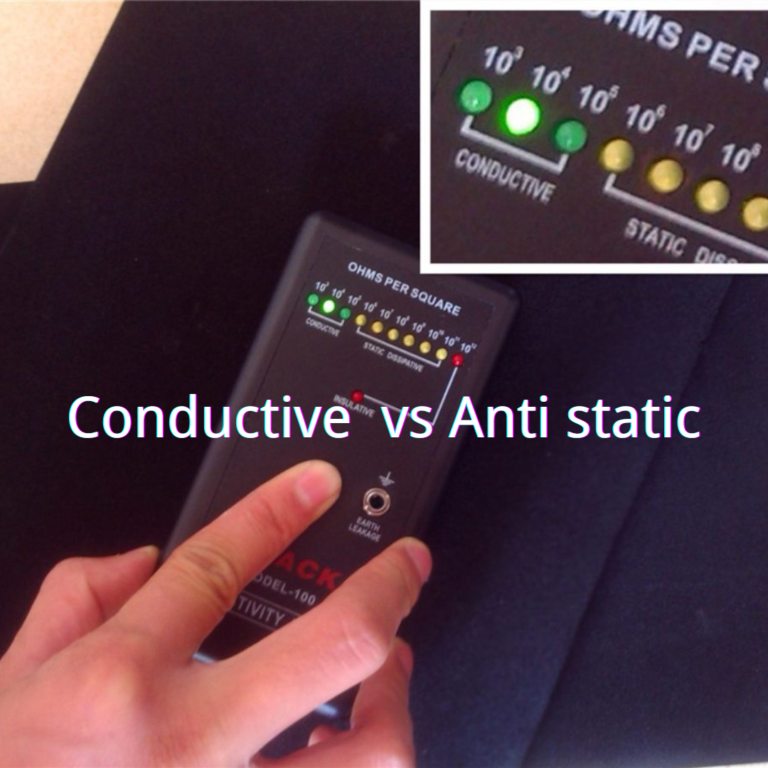

Types of anti-static foam products

There are several different types of anti-static foam products available, each with its own unique properties and applications.

Conductive foam

Conductive foam is the most effective type of anti-static foam. It is made from a special type of polyurethane that contains conductive particles, which help to dissipate static electricity quickly and efficiently. Conductive foam is typically used in applications where the highest level of protection is required, such as in the packaging of sensitive electronic components.

Dissipative foam

Dissipative foam is a less conductive type of anti-static foam that is still effective at dissipating static charges. It is made from a variety of materials, including polyethylene, polyurethane, and polystyrene. Dissipative foam is typically used in applications where a moderate level of protection is required, such as in the packaging of less sensitive electronic components.

Conductive/dissipative foam

Conductive/dissipative foam is a hybrid foam material that combines the properties of both conductive and dissipative foam. It is typically used in applications where a moderate level of protection is required, such as in the packaging of electronic components.

Factors to consider when choosing anti-static foam products

When choosing anti-static foam products, there are several factors to consider, including:

### Type of foam

The type of foam you choose will depend on the level of protection required for your goods. Conductive foam is the most effective type of anti-static foam and is typically used in applications where the highest level of protection is required.

### Density

The density of the foam will affect its ability to absorb shock and vibration. Higher density foam will provide better protection against these forces.

### Thickness

The thickness of the foam will also affect its ability to protect against shock and vibration. Thicker foam will provide better cushioning and protection.

### Application

The application will also impact the type of foam you choose. For example, if you are packaging sensitive electronic components, you may want to choose conductive foam for the highest level of protection.

Where to find quality anti-static foam products

Finding quality anti-static foam products can be challenging, but there are several places you can look. One option is to search for suppliers online. Many suppliers offer a wide range of anti-static foam products, and you can compare prices and features to find the best option for your needs.

Another option is to visit local electronics stores or shipping supply stores. These stores may carry anti-static foam products or be able to order them for you.

Tips for selecting the right supplier

When selecting a supplier for your anti-static foam products, there are several factors to consider, including:

### Reputation

Choose a supplier with a good reputation for quality products and customer service.

### Experience

Look for a supplier with experience in the anti-static foam industry.

### Pricing

Compare prices from different suppliers to ensure you are getting a fair price for your anti-static foam products.

### Customer service

Choose a supplier with excellent customer service to ensure you receive the support you need.

Pricing considerations for anti-static foam products

The cost of anti-static foam products will vary depending on the type of foam, density, thickness, and other factors. Conductive foam is typically more expensive than dissipative foam, and higher density foam will also be more costly.

When comparing prices between different suppliers, be sure to consider the total cost, including shipping and handling fees. Some suppliers may offer discounts for bulk orders, so be sure to ask about these options if you are ordering a large quantity of foam.

How to properly use and maintain anti-static foam products

To ensure the maximum protection for your goods, it is important to properly use and maintain your anti-static foam products. Here are some tips to keep in mind:

### Use proper packaging techniques

When packaging your goods, be sure to use the appropriate type of foam for your needs. Conductive foam is best for sensitive electronic components, while dissipative foam may be suitable for less sensitive items.

### Store foam properly

Store foam in a cool, dry place to prevent damage from environmental factors.

### Inspect foam regularly

Inspect your foam regularly for signs of wear or damage. Replace any damaged foam to ensure continued protection for your goods.

Conclusion: The benefits of investing in high-quality anti-static foam products

Investing in high-quality anti-static foam products is essential for protecting your electronic components and other valuable goods. With the right type of foam, you can prevent damage from static electricity, shock, and vibration, ensuring that your items arrive at their destination in pristine condition.

When selecting anti-static foam products, be sure to consider the type of foam, density, thickness, and other factors to ensure you are getting the best possible protection for your goods. By following the tips in this guide, you can find quality anti-static foam products near you and ensure the safety and integrity of your goods.