ESD foam plates, also known as ESD (Electrostatic Discharge) safe foam plates, are foam materials designed to provide protection against static electricity. They are commonly used in industries where static electricity poses a risk of damage to sensitive electronic components. ESD foam plates have properties that allow them to dissipate or neutralize static charges, minimizing the potential for electrostatic discharge.

ESD foam plates are typically made from polyurethane foam or polyethylene foam, which are infused with conductive additives or coatings. These additives or coatings create a conductive path that helps to safely dissipate static charges and prevent the buildup of static electricity.

eSD Foam Plates Specifications

ESD foam plates come in various specifications, and the exact specifications may vary depending on the manufacturer or supplier. However, here are some common specifications and characteristics to consider when looking for ESD foam plates:

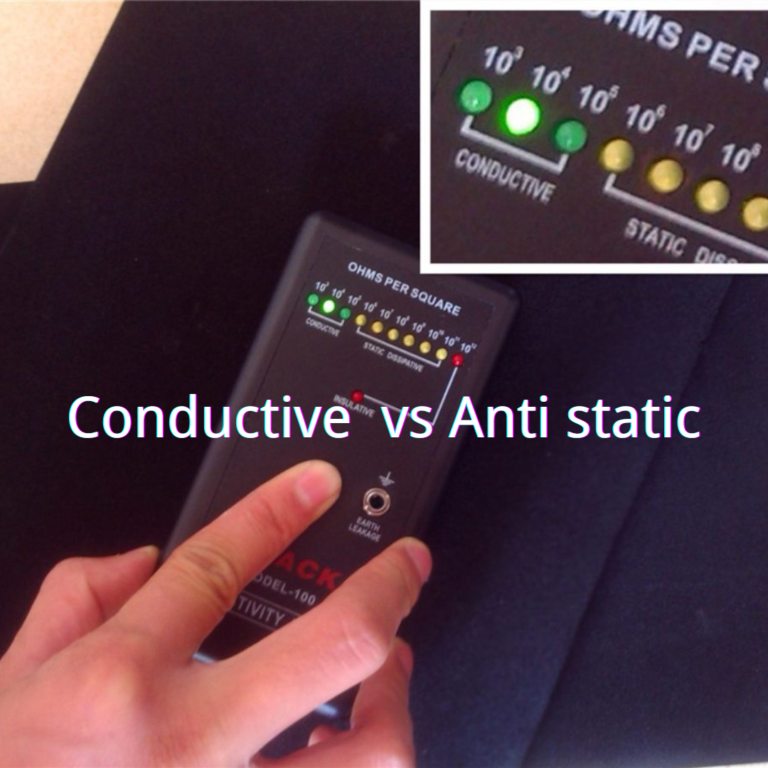

- Surface Resistivity: ESD foam plates are designed to have specific surface resistivity values, typically ranging from 10^4 to 10^9 ohms/square. This range ensures effective dissipation of static charges and prevents the buildup of static electricity.

- Thickness: ESD foam plates are available in different thicknesses, ranging from 0.3mm to 100mm as different requirements. The thickness will depend on the application and the level of cushioning or protection required for the specific electronic components being handled or stored.

- Density: ESD foam plates come in various densities,between 18kg/m3 to 300kg/m3, which determine the firmness and resilience of the foam. The density of the foam can impact its cushioning properties and durability. Higher density foams generally offer better support and protection.

- Color: ESD foam plates are often available in black color, if customers need other specific color, it can be customized. the choice is primarily aesthetic and does not significantly affect the ESD properties of the foam.

- Foam Type: ESD foam plates can be made from different foam materials, such as polyurethane foam or polyethylene foam. The foam type can influence factors like cushioning, flexibility, and chemical resistance. Polyurethane foam is generally softer and offers better cushioning, while polyethylene foam tends to have higher resilience and chemical resistance.

- Surface Texture: ESD foam plates may have different surface textures, such as smooth or textured finishes. The surface texture can affect grip, ease of cleaning, and visual appearance. If you want the surface be smoother, choose the polyethylene foam which is closed cell foam. if you want it be rough,then choose the polyurethane foam, which is open cell foam.

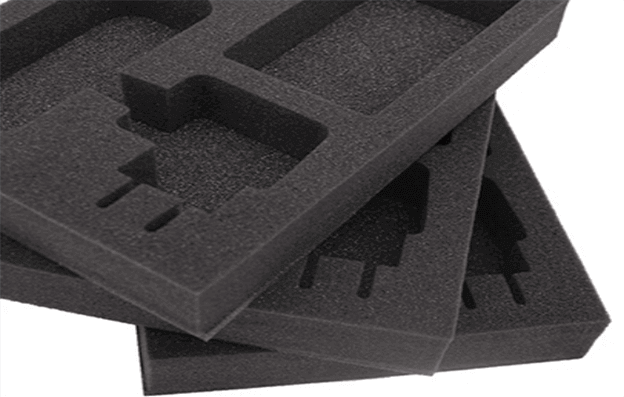

- Customization: ESD foam plates can often be customized in terms of shape, size, and cut-outs to fit specific requirements. Customization options allow for the creation of tailored packaging solutions or inserts that precisely accommodate electronic components.

It is important to consult with the manufacturer or supplier to ensure that the ESD foam plates meet the required specifications and standards for your specific application. Additionally, adherence to relevant industry standards, such as ANSI/ESD S20.20, should be considered to maintain an ESD-safe environment.

ESD foam plates Applications

ESD foam plates find applications in various industries where electrostatic discharge (ESD) protection is critical. Here are some common applications of ESD foam plates:

- Electronic Component Packaging: ESD foam plates are widely used for packaging sensitive electronic components such as integrated circuits (ICs), semiconductors, circuit boards, connectors, and other delicate parts. The foam provides cushioning and protection during storage, transportation, and handling, while also preventing electrostatic discharge that could damage the components.

- Workstation Mats and Liners: ESD foam plates are used as mats or liners on workstations and assembly areas where electronic components are handled. These foam plates provide an ESD-safe surface, ensuring that static charges are dissipated and controlled. They protect sensitive components from static damage during assembly, testing, and repair processes.

- Cleanroom Environments: ESD foam plates are utilized in cleanroom environments to package, store, and transport electronic components. These foam plates are designed to minimize the generation of particles or fibers that could contaminate the sensitive components. They are cleanroom-compatible and help maintain the required cleanliness standards.

- Static-Sensitive Equipment Protection: ESD foam plates are used to protect static-sensitive equipment, devices, or instruments from electrostatic discharge. They can be utilized as customized inserts or padding within cases or containers to provide a secure and cushioned environment, preventing damage from static charges during transport or storage.

- Tool Organization and Protection: ESD foam plates are employed to organize and protect tools, including precision instruments, small hand tools, and electronic testing equipment. The foam plates can be custom-cut to fit tool shapes, providing secure storage and preventing tool damage while also offering ESD protection.

- Automotive and Aerospace Industries: ESD foam plates find applications in the automotive and aerospace industries for the packaging and transportation of electronic components, such as sensors, control units, and connectors. The foam plates protect these components from static damage during production, assembly, and distribution processes.

- Medical and Healthcare Applications: ESD foam plates are used in medical and healthcare industries to protect and package sensitive electronic devices, instruments, and equipment. They help ensure the safe handling, storage, and transport of medical devices while providing ESD protection.

- Safety Equipment and Personal Protection: ESD foam plates are used in the production of safety equipment and personal protection gear. They are utilized to create ESD-safe storage cases, inserts, or padding for items such as ESD-sensitive garments, grounding straps, and wristbands.

These are just a few examples of the applications of ESD foam plates. Their ESD protection properties, along with their cushioning and customizable features, make them essential in industries where static control and component protection are paramount.