What’s Anti static foam tape ?

Anti-static foam tape is an adhesive tape that’s specifically designed to prevent the buildup and discharge of static electricity. Static electricity can accumulate on surfaces, particularly those made of insulating materials, and can potentially damage sensitive electronic components or cause other problems in certain environments, such as electronics manufacturing or handling.

Anti-static foam tape is made of foam material that has been treated with conductive or dissipative additives. These additives help to control the flow of static electricity by providing a pathway for the electric charges to dissipate, thereby preventing the buildup of static charge. The tape is often used for packaging, cushioning, and securing electronic components. It’s also used for creating grounded surfaces in workstations or manufacturing areas where static electricity could be a concern.

The tape is typically used in situations where traditional insulating materials could contribute to static buildup, potentially leading to electrostatic discharge (ESD) events. By using anti-static foam tape, the risk of damaging sensitive components or causing disruptions due to static electricity can be reduced.

It’s important to note that while anti-static foam tape can help mitigate static electricity issues, it might not provide full protection in highly sensitive environments. In such cases, additional ESD control measures, such as grounding equipment and using proper ESD-safe handling practices, might be necessary.

Different types of ESD (electrostatic discharge) foam tapes:

Conductive Foam Tape: This type of foam tape includes conductive materials or additives that allow it to provide a path for static charges to dissipate, effectively grounding the static electricity. It’s commonly used in applications that require a direct discharge of static electricity.

Anti Static Foam Tape: Anti static (Dissipative) foam tape has a higher resistance than conductive foam tape, allowing it to slowly and safely discharge static charges without creating rapid sparks. It provides a controlled path for static dissipation and is often used in environments where avoiding sudden discharges is important.

Double-Sided and Single-Sided ESD Foam Tape: This type of foam tape has adhesive on both sides or One size, making it useful for bonding two surfaces or one surface together while also preventing static buildup. It’s commonly used in mounting or securing components within electronic devices.

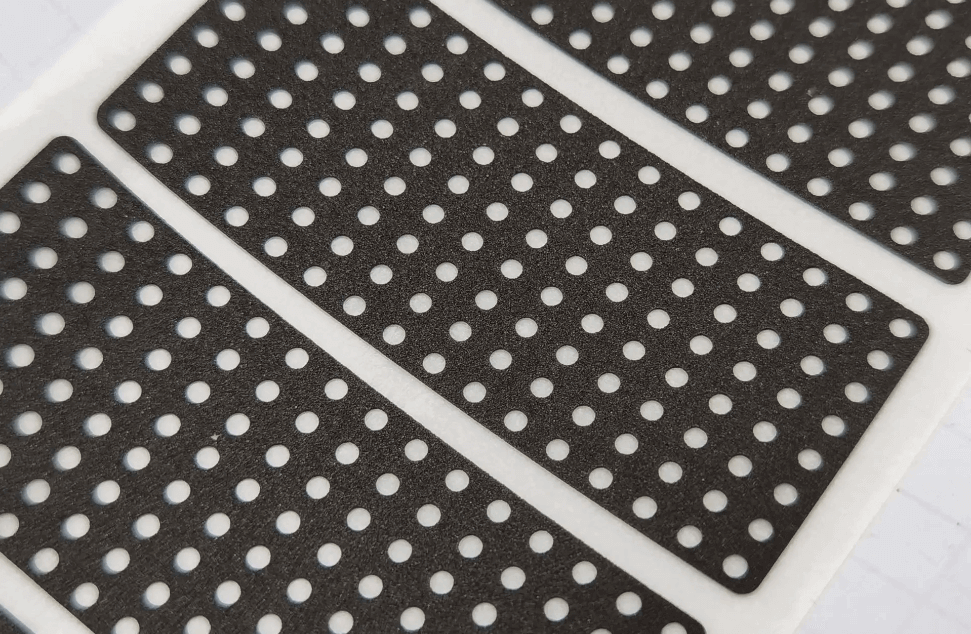

Custom-Cut ESD Foam Tape: Many manufacturers offer anti-static foam tape that can be custom-cut to specific shapes and sizes. This is particularly useful when foam tape is needed to fit a specific area or application.

Embossed Foam Tape: Some ESD foam tapes have an embossed or textured surface, which can help increase the surface area in contact with components. This can enhance the dissipative properties of the tape.

High-Temperature Foam Tape: In certain applications where components may be exposed to elevated temperatures, high-temperature ESD foam tape is used. This type of tape is designed to withstand higher temperatures without degrading its properties.

Static Shielding Foam Tape: This type of foam tape combines anti-static properties with a layer of metallic shielding, often aluminum, to provide protection against external electrostatic fields. It’s commonly used in electronics packaging to protect sensitive components from external ESD.

When considering which type of ESD foam tape to use, it’s important to assess the specific requirements of your application, including the level of ESD protection needed, the potential sensitivity of the components, and any regulatory standards that need to be met. It’s also advisable to consult with us to ensure you select the most appropriate type of foam tape for your needs.

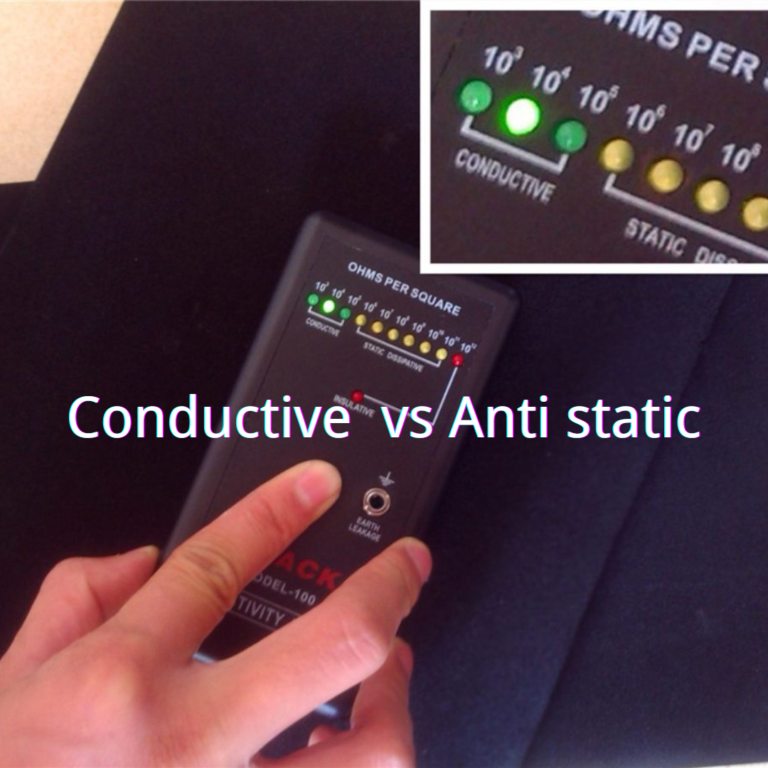

Anti static / Conductive Foam tape properties

| Item | Anti static types | Conductive types |

| Color | Black | Black |

| Thickness | 0.2-10mm | 0.2-10mm |

| Cell structure | Closed cell | Closed cell |

| Surface resistivity | 10^3-10^5 | 10^6-10^9 |

| Volume resistivity | 10^3-10^5 | 10^6-10^9 |

| Maxwidth | 1200mm | 1200mm |

| Material | PE Foam / EVA Foam | PE Foam / EVA Foam |

anti static foam tape features

Anti-static foam tape has several features that make it useful for various applications where static electricity control is important. Here are some of its key features and applications.

Static Dissipation: The foam material is impregnated with conductive or dissipative additives, creating a pathway for static charges to flow away from sensitive components or areas.

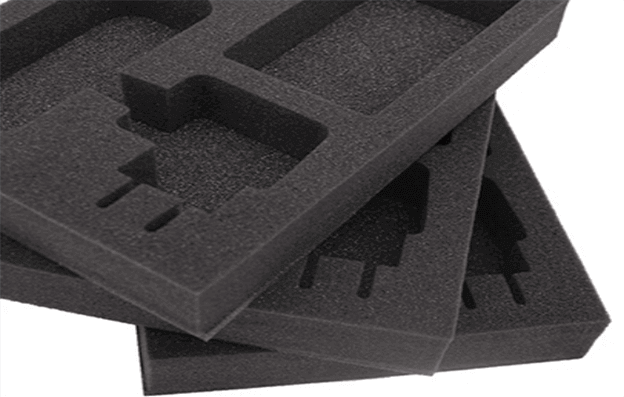

Cushioning: The foam material provides cushioning and protection to delicate or sensitive items. It’s suitable for packaging and transporting electronic components that need both static protection and physical cushioning.

Adhesive Properties: Anti-static foam tape is equipped with adhesive on one or both sides, allowing it to be easily applied to surfaces. The adhesive ensures that the tape remains securely in place.

Conformability: The foam material is often pliable and can conform to irregular surfaces, ensuring proper contact and better static dissipation.

Customizable Shapes: Anti-static foam tape can be easily cut or shaped to fit specific requirements, making it adaptable for various applications.

anti static foam tape applications

Electronic Component Packaging: Anti-static foam tape is commonly used to package and protect sensitive electronic components during shipping and storage. It prevents static discharge that could potentially damage the components.

ESD-Safe Workstations: It’s used to create ESD-safe workstations and assembly areas by covering surfaces where static buildup could occur. This helps prevent accidental electrostatic discharge when handling sensitive electronics.

Cushioning and Insulation: Anti-static foam tape can be used as a cushioning material between electronic components or between components and surfaces to prevent physical damage during transportation or assembly.

Gasketing: In electronics manufacturing, anti-static foam tape can be used to create ESD-safe gaskets between parts or in equipment enclosures to prevent static buildup and provide a barrier against dust and contaminants.

Grounding and Shielding: It’s utilized for grounding purposes, where it provides a conductive pathway to ground static charges. It can also be used to shield sensitive components from external static sources.

Medical Devices: In environments such as medical equipment manufacturing or handling, where electrostatic discharge could harm delicate medical devices, anti-static foam tape can be used for protection.

Automotive Electronics: Anti-static foam tape can find applications in the automotive industry for protecting electronic systems within vehicles from static damage during manufacturing and maintenance.

Aerospace and Defense: In aerospace and defense industries, where high-reliability electronic systems are crucial, anti-static foam tape can be used to prevent static-related failures.

Anti-static foam tape is a versatile solution that’s used in a wide range of industries to prevent static discharge and protect sensitive electronic components and equipment.