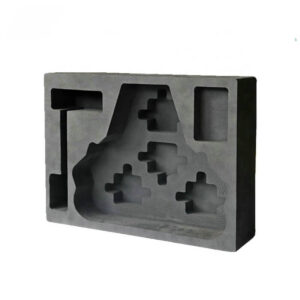

Anti Static PE Foam Tray

Anti-static PE foam tray is a type of foam tray made from anti static polyethylene (PE) foam material, which is be made as the tray shape, specially designed to prevent electrostatic discharge (ESD) and protect sensitive electronic components during storage, shipping, handling, and assembly.

Anti-static PE foam tray is molded or shaped to fit specific electronic components or devices. It is typically used to securely hold the components in place and protect them from damage during transportation and storage.

Contact Us for Latest Price!

- Satisfaction Guaranteed

- Fast Delivery

- Bulk Availability

Description

Anti-static PE foam Tray Specification:

- Thickness: 1-100mm, can be produced according to needs.

- Surface Resistance:103-5Ω./ 106-9Ω

- Size: Can be made according to needs.

- Hardness: 30-70 Shore C.

- Temperature Resistance: 120℃

- Color: Black

- Certification: ROHS, SGS, ISO9001, etc.

Antistatic PE Foam Tray Features

- Anti Static protection: Anti-static PE foam is designed to neutralize static charges and prevent damage to electronic devices from ESD. The foam is made with a unique blend of conductive and dissipative materials that helps to absorb and dissipate static electricity.

- Cushioning and shock absorption: Anti-static PE foam provides excellent cushioning and shock absorption, which helps to protect electronic components from damage during storage,transportation and handling. The foam material is soft and flexible, which allows it to conform to the shape of the component and provide a snug fit.

- Lightweight: Anti-static PE foam is lightweight, which makes it easy to handle and transport. It also helps to keep shipping costs down.

- Customizable: Anti-static PE foam can be customized to meet specific requirements, such as size, shape, and color. It can also be laminated with other materials, such as conductive films, to provide additional protection.

- Chemical and moisture resistance: Anti-static PE foam is resistant to chemicals and moisture, which helps to ensure that it will maintain its protective properties over time.

- Eco-friendly: Anti-static PE foam is made from polyethylene, which is a recyclable material. This makes it an environmentally friendly choice for electronics manufacturers.

Anti static pe foam tray Applications

Anti-static PE foam trays are widely used in various industries that require protection of sensitive electronic components from electrostatic discharge (ESD) and other forms of damage. Here are some of the common applications of anti-static PE foam trays:

- Electronic component packaging: Anti-static PE foam trays are used to package sensitive electronic components, such as microchips, circuit boards, and sensors. The trays are designed to prevent ESD damage during transportation and handling.

- Medical device packaging: Anti-static PE foam trays are used to package medical devices, such as surgical instruments, implants, and diagnostic equipment. The trays protect these devices from damage during transportation and ensure that they remain sterile until they are ready to be used.

- Aerospace industry: Anti-static PE foam trays are used in the aerospace industry to protect sensitive components and equipment from damage during transportation and storage.

- Automotive industry: Anti-static PE foam trays are used in the automotive industry to protect sensitive electronic components, such as sensors and control modules, during transportation and handling.

- Military and defense: Anti-static PE foam trays are used by military and defense contractors to protect sensitive electronic components used in military equipment, such as radar systems and communications equipment.

- Semiconductor industry: Anti-static PE foam trays are used in the semiconductor industry to protect sensitive components during transportation and handling. These components are used to manufacture electronic devices, such as computer chips and memory modules.

Overall, anti-static PE foam trays are essential for industries that require protection of sensitive electronic components from ESD and other forms of damage. They provide a reliable and cost-effective solution for transportation and storage of these components, ensuring that they remain safe and functional until they are ready to be used.