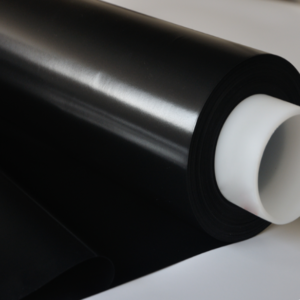

Anti Static PE Foam Roll

Anti-static PE foam roll is a basic shape of anti static PE foam material, that is made from polyethylene (PE) foam, are commonly used in the electronics manufacturing industry, where the risk of ESD damage is high.

Anti-static PE foam roll is quite easier for production,transportation and storage. Compared with other shapes of anti static pe foam, foam rolls are the most cost effective.

Contact Us for Latest Price!

- Satisfaction Guaranteed

- Fast Delivery

- Bulk Availability

Description

Anti-static PE foam rolls are a versatile and reliable electronic packaging material that provides protection against electrostatic discharge (ESD) and other forms of damage. Here are some of the anti static pe foam specifications, features, and applications as below.

Anti-static PE Roam Rolls Specifications:

Material: Anti-static PE foam rolls are made from a blend of conductive and dissipative materials that help to absorb and dissipate static electricity.

- Thickness: typically from 0.3mm to 100mm.

- Color: Black

- Surface Resistance:103-109 Ω

- Width: up to 1500mm

Anti Static PE foam Rolls Features:

- Excellent and permanent anti static performance with anti static inside.

- It promotes the slow release of electrostatic and protect the electronics.

- Excellent electrical conductivity, surface resistance: 103-109 Ω;

- Buffer good performance: independent and fine pore closure;

- High temperature resistance: PE maximum temperature 80℃

- Chemical resistance: resistant to organic solvents, acids, bases, etc.;

- No chemical corrosion: It has no corrosion to the components and packaging;

- Heat insulation, sound insulation, water absorption, moisture;

- Good processing performance, easy molding.

Material Specification of Anti Static PE Foam

Anti static PE foam is a close-cell foam. It is produced by compounding the PE resin with conductive fillers & blowing agents to extrude certain sheets,then cross-linking and foaming. The basic process can be summarized to the following

Anti static PE Foam Basic Production Process

-

- Pellitizing master batch by compounding PE resin with carbon black and AC foaming agents;

- Extrude the said batch to make certain sheets with different thickness & width;

- Cross link the said sheets under electric beam;

- Make the cross linked sheets foam in foaming furnace

Anti Static PE foam Raw material

|

No.

|

Material

|

Content

|

Remark

|

|

1

|

Polyethylene Resin

|

75—85%

|

Raw Material

|

|

2

|

Conductive Carbon Black

|

10—15%

|

Conductive filler

|

|

3

|

AC foaming agents

|

5—15%

|

Blowing Agent

|

|

4

|

Others

|

3—6%

|

Processing Agent

|

Anti Static PE foam Technical Index

|

No..

|

Data

|

||

|

CE Series (Conductive)

|

DE Series (Dissipative)

|

||

|

1

|

Color

|

Black

|

|

|

2

|

Density

|

40-60 Kg/m3

|

|

|

3

|

Surface Resistivity

|

103—10 6Ω/sq

|

10 6—10 9Ω/sq

|

|

4

|

Volume Resistivity

|

10 3—10

|

|

Anti Static PE foam Rolls Applications:

- Electronic component packaging: Anti-static PE foam rolls are used to package sensitive electronic components, such as circuit boards, memory modules, and sensors.

- Medical device packaging: Anti-static PE foam rolls are used to package medical devices, such as surgical instruments and diagnostic equipment.

- Aerospace industry: Anti-static PE foam rolls are used in the aerospace industry to protect sensitive components and equipment during transportation and storage.

- Automotive industry: Anti-static PE foam rolls are used in the automotive industry to protect sensitive electronic components, such as sensors and control modules, during transportation and handling.

- Military and defense: Anti-static PE foam rolls are used by military and defense contractors to protect sensitive electronic components used in military equipment.

- Semiconductor industry: Anti-static PE foam rolls are used in the semiconductor industry to protect sensitive components during transportation and handling.

Overall, anti-static PE foam rolls are a reliable and cost-effective solution for protecting sensitive electronic components from ESD and other forms of damage during transportation and storage. Their customizable features, excellent cushioning properties, and resistance to chemicals and moisture make them ideal for a wide range of applications across various industries.